WUHAN HENGTU INNOVATION TECHNOLOGY CO., LTD (HIT). IS LOCATED IN OPTICS VALLEY, CHINA. IT IS A COMPREHENSIVE SOLUTION PROVIDER SPECIALIZING IN ONE-STOP CONSTRUCTION OF GLOBAL FIBER OPTIC PRODUCTION LINES. THE COMPANY HAS A TOP-NOTCH TECHNICAL TEAM IN THE INDUSTRY, MASTERING THE WORLD‘S LEADING FIBER OPTIC PRODUCTION TECHNOLOGY AND PROCESSES, AND CAN PROVIDE A COMPLETE SET OF COMPREHENSIVE SOLUTIONS SUCH AS PRODUCTION LINE DESIGN, EQUIPMENT SELECTION, SUPPLY CHAIN INTEGRATION, FINANCIAL SUPPORT

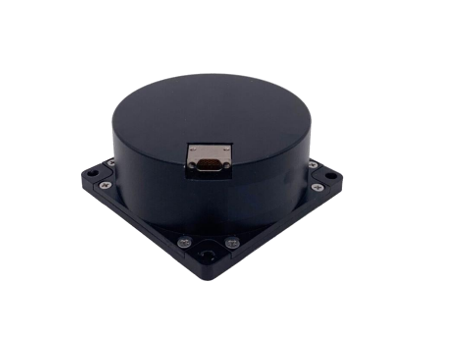

The latest generation of gyroscope is mainly used in inertial navigation system and attitude control system, which has the advantages of small size, light weight and high precision.

The fiber coil used in the application of various precision fiber optic gyroscopes developed by the company is wound with thin-diameter polarization-maintaining fiber ultraviolet light-cured glue to meet the assembly, performance and various application environment requirements of different precision gyroscopes.

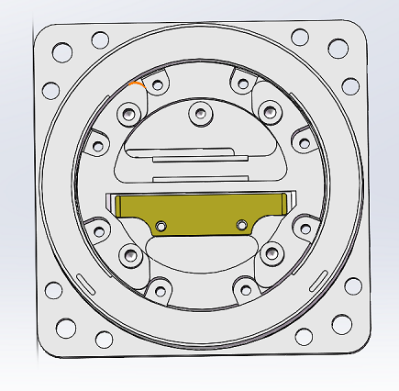

The product is used in fiber optic gyro, with high integration, small size, magnetic shielding and easy installation, can be customized according to customer needs.

The multi-functional integrated optical device is made by lithium niobate annealing-proton exchange process, and has the functions of light splitting, phase modulation, polarizing, etc. It is mainly applicable to fiber optic gyroscopes, fiber optic sensors and other fields.

PIN-FET optical receiver modulehas the characteristics of low noise and high sensitivity, which can be applied to fiber optic gyroscope, fiber optic hydro, optical current transformer, laser positioning and ranging system.

.png)

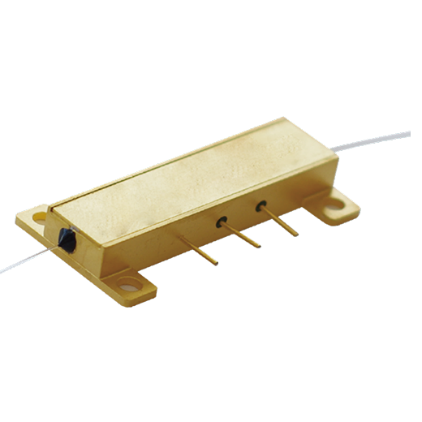

Super luminescent diodes have the characteristics of high power and wide spectrum, and can be applied to fiber optic gyroscopes fiber optic current transformers, optical coherence tomography.

The products can be used in fog coil and fog waveguide, with excellent attenuation characteristics, birefringence characteristics, temperature stability, batch consistency and anti-irradiation performance, can meet a variety of application requirements.

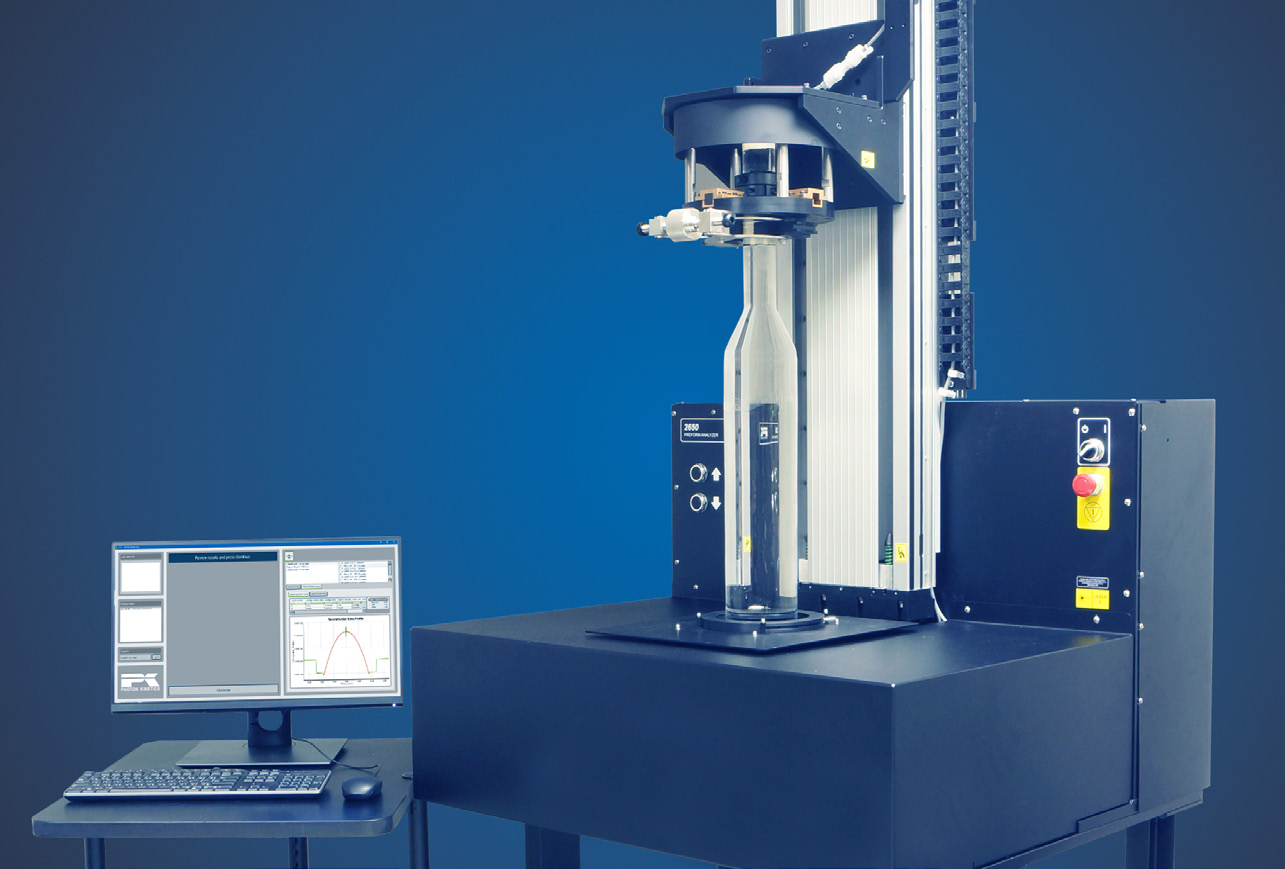

Fiber optic tester is a series of testing equipment, including fiber optic performance, fiber optic mechanical performance, and other special environmental performance testing equipment. These devices ensure that optical fibers used in related fields or scenarios can achieve excellent performance.such fiber screening tester,optical preform analyzer,fiber PMD analyzer,fiber multiparameter tester,chromatic dispersion analyzer.

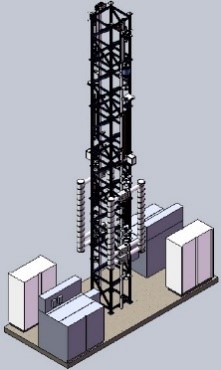

A core equipment used to soften and draw fiber optic preforms into fine fibers at high temperatures, mainly used for producing conventional quartz fibers and specialty fibers. The main components of an optical fiber drawing tower include a high-temperature furnace system, a traction system, a coating system, and a precision control system. The optical fibers produced by it are widely used in fields such as communication, aerospace, unmanned aerial vehicles, autonomous driving, missile guidance, and submarine cables. Especially some special optical fibers can maintain stable signal transmission in extreme environments, which has important application value.

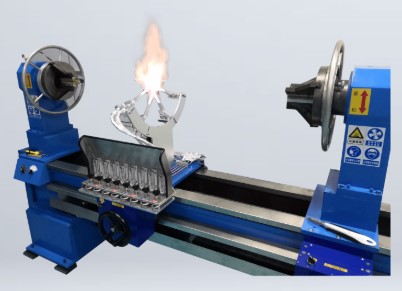

This fire lathe is specially used for heat treatment of optic fiber prefabricated tube-rod. It is suitable for hot working processes such as melting, drawing, taper drawing, nozzle and polishing of quartz tube-rod with outer diameter below Φ50mm. The machine tool bed is cast with cast iron, which can effectively reduce the process error caused by mechanical interference. And the software of this equipment is independently developed, with expandable function, simple and convenient to operate.

The MCVD method can deposit higher purity silicon dioxide (SiO2) on the inner wall of quartz tube(commonly called liner) with high quality (high purity, low moisture and low impurities), Other high-purity substances that can change the refractive index or vitreous viscosity, such as germanium dioxide (GeO2), phosphorus pentoxide (P2O5), silicon oxide fluoride (SiOF2),etc. are doped to form cores and cladding with different refractive indices, so as to achieve total reflection, low loss and high capacity when optical signals propagate in the fiber core.

Based on the technological principle of the mature vertical pipe washing machine and the requirements of the inner-tube method of the optical fiber preform for the substrate pipe, it is designed the PVC nozzle in the cleaning cavity during the cleaning process, acid, alkali from the bottom of the injection, overflow cycle, make cleaning, corrosion more uniform, equipment placed in the purification plant, can complete the quartz tube cleaning process.